October 19 2008. I can't find my steam engine. I either stored it too well, or someone else is storing it somewhere.

As soon as I got a big old metal lathe, I wanted to make a new steam engine. I will try a different engine from McCabe's steam engines, called "an old design."

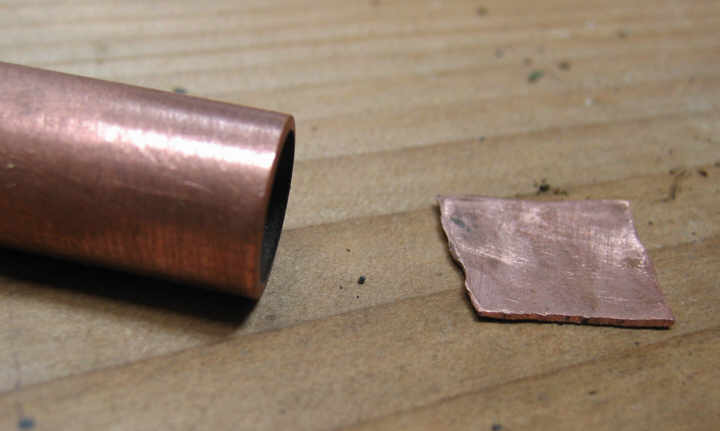

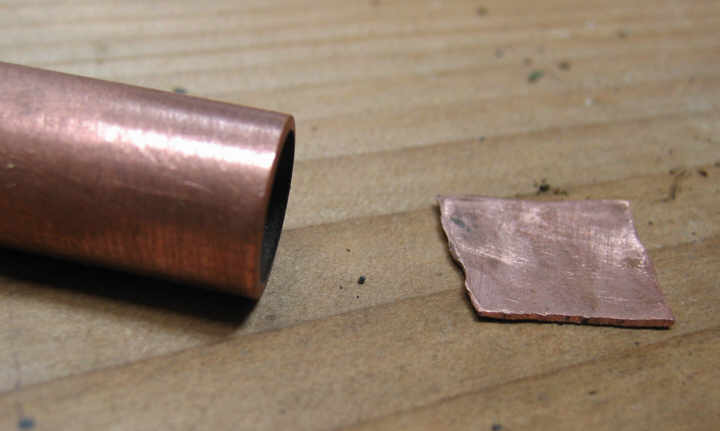

I made a piston out of copper pipe, like I did for my first engine. Here is the pipe and a piece of hammered and sanded copper sheet for the top:

The top is on the bottom in this picture, soldered on:

Turned smooth in the lathe:

Fits in the cylinder, which is a piece of galvanized steel pipe, lightly honed with the lathe and a drum sander:

Here is the valve piston, cut from an old lag screw:

I later discarded this piston as I had trouble connecting it to the bell crank. I ended up using an old nail.

I used an air grinder to cut a channel for the valve cylinder:

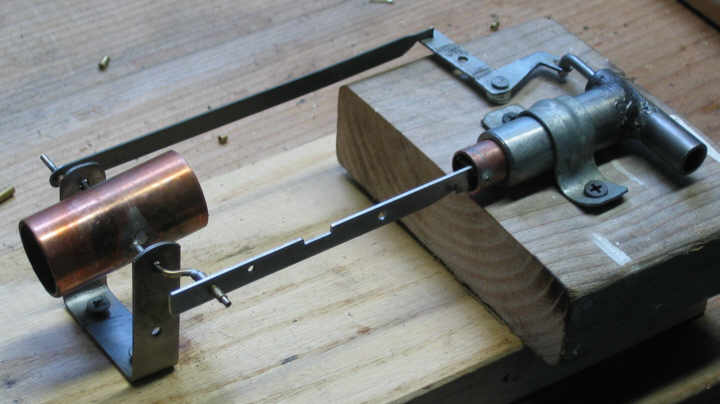

October 23-25. I welded the two cylinders together and mounted everything on wood. I made a bracket to hold the crankshaft, a brass rod. I had to be able to solder the "flywheel" to the brass crankshaft so I made it out of a piece of copper pipe. First I tried to make brass plates on the ends of the crankshaft as per the drawings from McCabe's site, but that was tedious. Instead, I bent the ends of the crankshaft following McCabe's diagrams as a guide, to accept the pushrod and connecting rod. I hooked it up to compressed air and it ran the first time I tried it! Here is an animated gif of the running engine:

Here is a close up:

I cleaned up the parts and mounted them on a piece of mahogany:

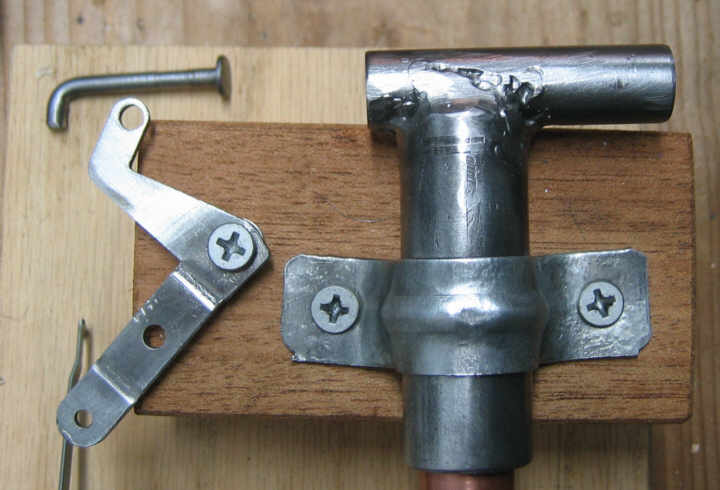

Here is a close up of the engine showing the "bell crank" that pushes the valve piston. The valve piston is in the background, a bent nail. You can also see my great welding job:

As you can see, this machine is made of scrap parts from a junk drawer.

I have not figured out the boiler yet. I have an old piece of steel brake line. I threaded the valve cylinder so I can use the brake line as a steam line from the boiler:

I still have to figure out where this brake line will go and how it will get there.

October 26-27. I have an old piece of large diameter copper pipe. I put it on the lathe and sanded it with plumber's sanding cloth. Here it is, sanded:

To connect the boiler to the engine, I will try jamming the steel brake line into a 1/4" copper tube. I drilled out the existing hole in the boiler to 1/4" and soldered in the copper pipe. I drilled a small hole for a short piece of brass tubing. This is part of my simple pressure relief valve:

I made the ends of the boiler with copper from copper pipe, as follows. Cut a piece of pipe with tin snips:

Spread it open with pliers:

Hammer it flat:

Clean it up with the wire brush:

Then I cut out a circle with the tin snips and solder it to the end of the boiler. Here is the boiler mounted on the engine:

I added a plugged rubber hose to the brass tube (pressure relief valve). For the left end of the boiler, I drilled the copper sheet and tapped it for a filler port before I soldered it on. I drilled and tapped a small square sheet of copper and soldered it to this end to add threads to the port hole. I tried to run the engine, but the system has a few leaks. The filler port needs a rubber O-ring, and I will have to improve the steel to copper connection.

November 2008. I can only get this thing to run on compressed air. It doesn't take much air, a few psi. I may have to redesign it to run on steam :-(

October 2009. I rehoned the valve cylinder by drilling it out a little. Then I made a new valve piston out of a 16 penny nail. The nail head was too small to fit well in the cylinder so I hammered it out a little, then turned it on the lathe to make it fit snuggly in the cylinder. With not much more tweaking, I got the engine to run nicely with a hot boiler: